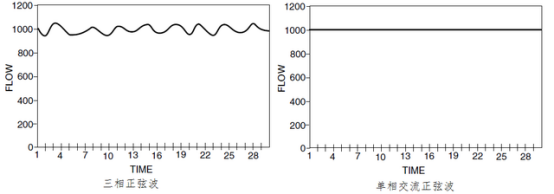

1. Current frequency

The rotation of the motor is directly related to the electricity, modern control through the speed controller to influence the motor input and control the motor speed, the following figure with an oscilloscope to observe the motor in a single-phase AC frequency sine wave and three-phase sine wave wind speed and current relationship, up and down the crest of the wave represents the wind speed, the current frequency of 360 degrees, the current frequency in the United States is 60 times per second, called 60 Hz, in other parts of the world, this The speed is 50 times per second (50 Hz), and the horizontal line in the center, also known as the “zero lines,” a sine wave passes through it 120 times per second.

2. Multi-speed motors

Most motor manufacturers offer motors with more than one available speed, and there is virtually no separate controller to change these speeds. Multi-speed motors use either tapped windings or multiple alternate windings, and the speed can be changed manually with a switch or controlled via a circuit board. Motors typically used for multi-speed are PSC and shaded-pole single-phase motors, with PSC motors being the most common and can have either tapped or alternate windings and shaded-pole motors made with tapped windings.

There are limitations to the speed combinations offered by the manufacturer, and the actual speed required may not always be available, which is a limitation of multi-speed motors in any case; another disadvantage is that the switch used is usually required to manually change the speed, and these motors work well with fans, which are used to exchange a certain amount of air without variation for a given time, and this type of fan motor is relatively economical. However, the exact airflow is difficult to match because it is not flexible in terms of speed.

3. Passive device speed control

Passive device speed controls are usually the cheapest purchase to implement but are often the most expensive to use because they waste power. They control the electromagnetic characteristics of the motor by varying the input voltage. This reduces the amplitude of the entire sine wave, which actually changes the height of the frequency sine wave, an old technique that is being replaced by more modern methods that use more efficient and less expensive switches due to its low-efficiency rating.

The most common motors used with passive device speed control are PSC, shaded pole and three-phase motors. Regardless of which motor is used, when using a particular type of control, the load must not be greater than the motor’s rating at start-up, or failure will occur. This is typically 150-200% of the full-speed running torque. This type of control is typically applied to low-power motors, and we usually do not have to worry about load or efficiency. While passive device controls are cheap and reliable, they usually require someone to operate them manually, and precise speeds can be difficult to achieve due to inconsistent voltage output.

4. Series resistors

Transformer: It can be used instead of a resistor and generally works in the same way. It consists of two coils, electrically insulated from each other, arranged in such a way that a change in current in one coil will change the voltage in the other coil. The decrease or increase in voltage is what changes the motor speed. The advantage of a transformer over a series resistor is that it does not waste power as heat during low-speed starting, which also means that the load can be started at low speed. The disadvantages of this type of control are that it is usually large, requires manual operation, and is not as economical as a series resistor.

Varistor: When this device is activated, it changes the voltage across the motor winding, thus producing motor slip. Usually, a varistor consists of a resistive element equipped with two contacts, one sliding and one fixed. As the sliding contact moves along with the resistive element towards the fixed contact, both the distance and the speed of the current leaving the element change, and this change in current speed can be converted into a variable speed when the motor is connected in a straight line. The disadvantage of this control is that the motor needs to be started at high speed and then decelerated. Otherwise, the contacts will overheat and burn out. Another disadvantage is that the varistor must be operated manually.

Potentiometer: A potentiometer is very similar to a varistor, except that it has a resistive element that is connected to the circuit through 3 contacts instead of 2. The arrangement and the way the current changes are slightly different. The end of the resistive element is connected to the circuit, and the third contact is connected to the output of the circuit, usually a removable contact that slides through the resistive element.

5. Solid State Control

Over the past few years, there have been tremendous advances in solid-state control technology and how it can be used to control motors, and most of the product development now being done on speed controllers involves solid-state control, with some controls even being integrated into the motor itself. Solid-state controls are often very reliable, can give accurate speeds, and are increasingly economically feasible to use with fractional horsepower motors. In the past, these types of controls were typically only used with fractional horsepower motors, where the power savings proved their usefulness, and as advances in electronics and cost reductions changed the way they were used.

Most different types of solid-state controls incorporate frequency and/or current changes to control the motor speed, and they can even change the frequency above the normal line frequency, which means we can increase the speed beyond the motor rating. Motors typically used with solid-state control are shaded pole, PSC and three-phase. Although these types of controllers are more accurate than the less sophisticated controllers used in the past, there are still some drawbacks or problems with their use when it comes to speed and torque control. For example, most manufacturers of these speed controls are not aware of the damage that can be done to the motor by changing the harmonic frequency.

Some other disadvantages to being aware of are that currents exceeding specified values can be very harmful to the motor winding laminate, voltage spikes from the inverter can cause a lot of damage to the winding, harmonics are higher than those already tested in motor components that can cause damage to bearings or laminate, sound and vibration can be altered, resulting in losses and of course a greater risk of fire.

6. Mechanical devices

Mechanical devices are one of the oldest forms of controlling the speed of fans and blowers, and they can be used alone or in conjunction with other types of space. In most cases, they have many advantages over electronic forms of speed control. For example, you don’t have to worry about electronic equipment failing and experts determining which part has failed. With mechanical devices, you can usually see which part has failed, and most mechanical people can fix the problem if needed.

Unfortunately, during normal operation, the speed is usually not adjustable, and the mechanism requires a lot of maintenance, such as lubrication.

Pulleys: This is the most common form of speed control in belt drives, and there are even pulleys that are fully adjustable where you can get the exact speed. However, when changing the pulley diameter, it is usually necessary to change the belt length as well. Pulleys have a huge advantage in large fans or blowers where the speed needs to be slower or faster than that provided by a standard motor or where a direct drive cannot be used. They can also easily carry large loads as long as the belt tension on the pulley is correct. Most of us are familiar with this type and know that it is not adjustable while the fan or blower is running, which is a huge waste, and this arrangement is also usually one of the highest maintenance.

Transmission products (gear reducers, gears, clutches, etc.): This form of speed control is not typically used for fans and blowers, but it should not be excluded from consideration. Most are familiar with transmission products because they are used in applications where, unlike fans, the load does not change when the speed is slowed down. These are usually reliable but often very expensive and cumbersome. They are often high maintenance and often require manual adjustment to make speed changes.